«What is a soccer ball made of?», they asked me. Great question! I bet it has crossed your mind too.

After all, I do run this soccer gear blog and write lots of reviews on the best soccer balls.

So it’d be perfectly normal if I knew everything about soccer ball construction too.

I decided to go further ahead and researched it even deeper.

Here’s my best possible resource about the construction of the soccer ball with all the nitty-gritty details to get that pertinent question “what is a soccer ball made of” totally answered.

What You’ll Learn From This Post

Soccer Ball Construction

There are four main components that make up a soccer ball:

- Cover

- Stitching

- Lining

- Bladder

If you fully understand these components and how they work together, it will help you choose the best soccer ball for your needs and uses.

Covers

You may call it whatever you like and you’d be right:

Surface, casing, cover or covering.

This is the outermost part of a soccer ball.

A cover is what gives the ball its appearance and it is there to protect it from wear, abrasion and other singularities that occur during a football’s lifetime.

Back in the day, the material used to make soccer ball covers was full grain leather.

It looked nice and kept the ball’s shape well when there was no other kind of technology.

There was a big problem with using regular leather, though:

When it rained, footballs became too heavy due to the water absorption characteristics of leather.

So much so it even caused head injuries to the misfortunate folks who decided to use their heads to kick it.

Thankfully, technology around the construction of soccer balls has evolved a lot in the past few decades.

During the 1970s, manufacturers began using Polyurethane — a synthetic material – to coat leather increasing the ball’s protection from scratches and scuffs and improving its water resistance capabilities under rain conditions.

In the present day, coverings use synthetic leather which is made from PVC (Poly Vinyl Chloride) or PU (Polyurethane).

Thanks to this improvement, soccer balls can sustain even higher water uptake and present a better touch and feel during play for longer periods.

Professional soccer balls — premium match balls or official match footballs — use synthetic leather coated with Polyurethane, which gives them a better feel.

Best soccer balls used in competition are constructed with one of these types of Polyurethane: Microfiber, Korean Ducksung, Japanese Teijin Cordley, AI-2000, etc.

Other types of synthetic leather used in the construction of soccer balls include Leather Art Pakistan Synthetic Leather and English Porvair.

Cheaper footballs use PVC, a highly durable plastic-like material which makes them harder to play with and gives them less feel.

Practice or promotional balls use PVC or (stitched or molded) rubber in their surface.

Indoor soccer balls’ covers are generally made using a colored felt material, the same as what tennis balls use in their coatings.

Felt is preferable on smooth surfaces since it makes the ball much more controlable.

Panels

Panels are the different segments of a soccer ball’s cover, their construction may deeply affect the flight of a soccer ball. The number of panels varies depending on each design.

Kinds of Soccer Ball Designs

- Buckminster ball: The most common soccer ball design for a large period in Soccer History -– has 32 panels and was used at professional level for quite some time.It consists of 12 pentagonal and 20 hexagonal segments.

The Buckminster design was also known as truncated icosahedron although it’s much rounder.When these segments are sewn together and the ball is inflated they form a nearly perfect spherical shape.

The Buckminster design was also known as truncated icosahedron although it’s much rounder.When these segments are sewn together and the ball is inflated they form a nearly perfect spherical shape. - 26 & 18-panel designs: There are also 26 and 18-panel balls that have been used in several professional soccer leagues.

- Very few panels: Soccer ball covers are in constant evolution.During the last few years, we have noticed that fewer and fewer panels have been used in the construction of soccer balls. Fewer panels mean fewer seams, which makes balls become even more of perfect spheres and offer them less water uptake.

How Soccer Balls Panels Are Put Together

How soccer balls panels are put together affects their shape, feel, touch and water absorption capabilities.

There are several ways to do so.

It can be achieved through glueing, stitching, or thermal bonding.

- Glued panels: onto the lining are generally used on cheaper, lower-end, practice balls offering them a harder feel.

- Stitched panels: can be done either with the use of machines or manually. The majority of mid-priced soccer balls are machine-stitched while more expensive, higher-end balls are hand-stitched. Hand-stitching makes seams become stronger and tighter. A 5-ply twisted polyester cord is used for stitching together highest quality footballs. A Kevlar reinforced polyester thread is used to stitch together some type of balls.

- Thermal bonded panels: The UEFA Euro’2004 Roteiro soccer ball was the first ball ever to have panels thermally bonded together. Following its example, FIFA World Cup 2010 Jabulani and the FIFA World Cup 2014 Brazuca soccer balls were also constructed using the same construction process.

Linings

Inner lining is placed between the bladder and the cover of footballs and composed of multiple layers of cotton and / or polyester bonded together.

The material and thickness used determines how strong, durable, responsive and bouncy a soccer ball is over the course of its life.

- Professional soccer balls have inner linings with multiple layers. Usually four or more layers of polyester and cotton. Polyester is what makes the ball responsive and durable. Cotton offers it softness of feel.

- Cheap, promotional or practice balls have fewer layers of lining. Generally only two layers of polyester. This makes the ball feel harder, more difficult to control but still durable.

- A foam layer is included in many footballs for greater ball control and cushioning.

Bladders

A soccer ball’s bladder is its innermost part and the component that holds air.

Bladders are built out of butyl or latex, being butyl the most commonly used material.

Butyl bladders retain air very well and for much longer periods of time (several weeks) and offer greater feel quality when compared to latex bladders.

However, butyl bladders are less responsive when kicked as soon as they get deformed — which occurs more easily.

This kind of bladder material is used in the majority of middle to upper priced footballs.

Latex bladders, due to their responsiveness and better surface tension, are the preferred choice in professional competitions.

Latex bladders’ disadvantages are that they tend to lose air much faster (so they need to be filled frequently) and latex isn’t as durable as butyl.

Natural latex rubber bladders have the softest responsiveness and feel.

Nevertheless, due to their micro pores letting air slowly escape, their weak spot is air retention. They need to be re-inflated with greater frequency, once a week minimum.

Carbon-latex bladders, as the name suggests, have carbon powder inside of them to help close many of their micro pores preventing them from losing air so quickly.

This offers soccer balls using carbon-latex bladders softer feel, proper bounce and same angle re-bounce benefits.

Polyurethane (PU) bladders are also being used in balls made by some manufacturers.

Futsal and indoor soccer ball bladders are filled with foam instead of air to reduce their bouncing capability because of the hard flooring those soccer variants are played on.

Valves

A valve is a small needle-like structure through where air is pumped when inflating the bladder.

Butyl valves are the most used ones in soccer balls because of their air retention capabilities. This rubber material easily opens or quickly closes when the inflating needle is inserted or removed due to its elastic characteristic.

Silicone or silicone-treated valves are used in high end and in many professional footballs for even better air retention and superior performance.

This kind of valves allow for smoother insertion of the air pump needle and greater air loss protection.

A good tip for inflating a brand new soccer ball for the first time is to put a few drops of silicon oil in the valve to make it easier to insert the needle and keep air longer inside the bladder.

How Hand-Stitched Soccer Balls Are Built

When putting together a hand-stitched football, the first step is to roll out the cover’s material.

To achieve a smooth though tough casing, the cover material is generally made from various layers of panels (synthetic foam-filled leaves) joined together with glue.

Before being cut into the exact amount required to manufacture one soccer ball, the ball’s graphics, logos and brand names are pre-printed –- most of the times by using a silk-screening process — onto the panels.

For improved protection of the printing itself and of the cover’s material, another layer of clear urethane (or a similar polymer) is applied over it.

After that, individual panels are cut out and stitching holes are pre-punched.

The cover is then turned inside out so that the stitching is done and none of the stitches is visible from the outside of the ball

To reach the ultimate goal of making the final knot vanish into thin air a different type of needle is used to finalize each of the panels’ stitching.

Finally, the now stitched casing is reversed and the bladder is inserted and pumped with air.

The Last Stitch

Many times it is asked how is the last stitch stitched when hand-stitching a soccer ball. This video here shows how this is done.

Professional stitchers can typically manufacture four balls per day.

How Adidas Brazuca is manufactured in China

Check out this video and watch «How Adidas Brazuca is manufactured in China».

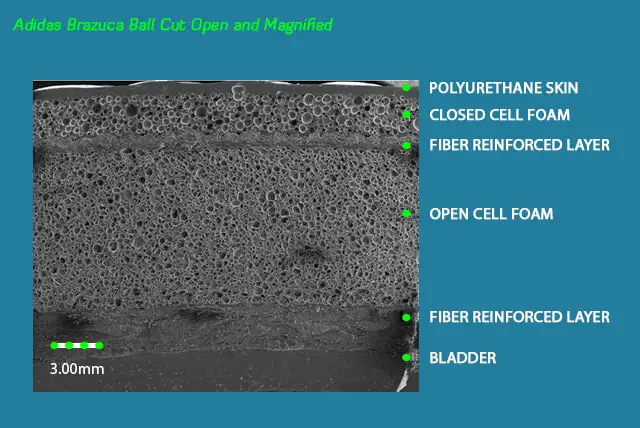

The following picture shows you the Adidas Brazuca football magnified with the use of an electron microscope after being cut open.

Notice how this soccer ball is made of a pair of foam layers and a pair of fiber-reinforced composites layers that go between the bladder and the outer cover.

Adidas Brazuca cut open and magnified. Photo by Vasanth C. Shunmugasamy, Post-Doctoral Research Associate

Adidas Brazuca cut open and magnified. Photo by Vasanth C. Shunmugasamy, Post-Doctoral Research Associate

And here is… the finished product!

The beautiful Adidas Brazuca, the official match soccer ball of the 2014 FIFA World Cup in Brazil.

Adidas Brazuca FIFA 2014 World Cup Official Match Soccer Ball

Adidas Brazuca is made from 100% polyurethane, high-end materials for the cover, bladder and backing.

Its cover has a thermally bonded seamless surface that gives it a more predictable flight trajectory, awesome feel and great water uptake capability.

Needless to say… the Adidas Brazuca passed weight, shape & shipe retention and water update tests with the highest FIFA ratings.

It wouldn’t be the official match ball during the Brazilian World Cup if it wasn’t that good, would it? 🙂

High Quality Approval Status

For brands aiming high quality approval status like International Matchball (IMS), FIFA Inspected, FIFA Approved or NFHS Authentication for their soccer balls a new process is started.

Those balls undergo complex and rigorous laboratory tests to see if they fit in those top level standards.

Conclusion

By now, you should already thoroughly know what is a soccer ball made of and how is a soccer ball manufactured.

We saw that the material used in soccer ball construction is typically synthetic leather, polyurethane (PU), poly vinyl chloride (PVC) for their covers.

Polyester, cotton and foam for the linings.

Butyl, latex, natural latex rubber, carbon-latex and PU for the bladders.

Finally, valves are made from butyl and silicone.

You could actually see how is a football hand-stitched — especially how is the last stitch sewn — and how most modern soccer balls (like Adidas Brazuca) are built too.